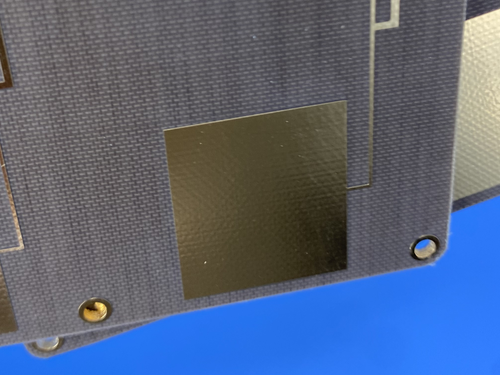

TLX-9 2-Layer PCB: High-Performance Circuit Boards for Advanced Applications

1.Introduction to TLX-9

TLX-9 is a state-of-the-art composite made from PTFE and woven glass laminates, known for its exceptional electrical and mechanical properties. This material is highly suitable for various manufacturing methods, including shearing, drilling, milling, and plating, making it versatile in PCB applications. TLX-9 laminates offer dimensional stability and minimal moisture absorption during fabrication, ensuring high performance and reliability for electronic devices.

2. Features

Dielectric Constant: 2.5 at 10 GHz

Dissipation Factor: 0.0019 at 10 GHz

Moisture Absorption: Less than 0.02%

Dielectric Breakdown: Greater than 60 kV

Volume Resistivity: 10^7 Mohm/cm

Surface Resistivity: 10^7 Mohm

Arc Resistance: Over 180 seconds

Flexural Strength: Lengthwise over 23,000 lbs/in; crosswise over 19,000 lbs/in

Peel Strength: 12 lbs/linear inch for 1 oz copper

Thermal Conductivity: 0.19 W/m/K

Coefficient of Thermal Expansion (CTE): 9-12 ppm/°C (x-y), 130-145 ppm/°C (z)

UL-94 Flammability Rating: V-0

3. PCB Construction Details

| Specification | Details |

|---|---|

| Base Material | TLX-9 |

| Layer Count | 2 layers |

| Board Dimensions | 78mm x 39mm (1 PCS), ± 0.15mm |

| Minimum Trace/Space | 4/7 mils |

| Minimum Hole Size | 0.25mm |

| Blind Vias | None |

| Finished Board Thickness | 0.9mm |

| Finished Copper Weight | 1 oz (1.4 mils) outer layers |

| Via Plating Thickness | 20 µm |

| Surface Finish | Immersion Gold |

| Top Silkscreen | White |

| Bottom Silkscreen | None |

| Top Solder Mask | None |

| Bottom Solder Mask | None |

| Electrical Testing | 100% electrical test prior to shipment |

4. PCB Stackup

| Specification | Details |

|---|---|

| Copper Layer 1 | 35 µm |

| Taconic TLX-9 Core | 0.787 mm (31 mil) |

| Copper Layer 2 | 35 µm |

5.PCB Statistics

Components: 16

Total Pads: 36

Through Hole Pads: 25

Top SMT Pads: 11

Bottom SMT Pads: 0

Vias: 23

Nets: 2

6.Manufacturing & Compliance

Artwork Format: Gerber RS-274-X

Quality Standard: IPC-Class-2 compliant

Availability: Worldwide production and shipping

7.Benefits

Low Dielectric Constant

Low Dissipation Factor

Minimal Moisture Absorption

High Dielectric Breakdown

Excellent Peel Strength

Controlled Coefficient of Thermal Expansion (CTE)

8.Typical Applications

LNAs, LNBs, and LNCs

Personal Communications Service / Personal Communications Network (PCS/PCN)

Large Format Antennas

High Power Amplifiers

Passive Components